High resolution imaging、High speed imaging、3D imaging、High sensitivity imaging、Spectral imaging、

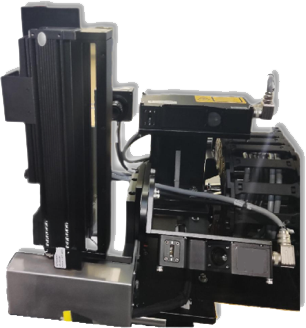

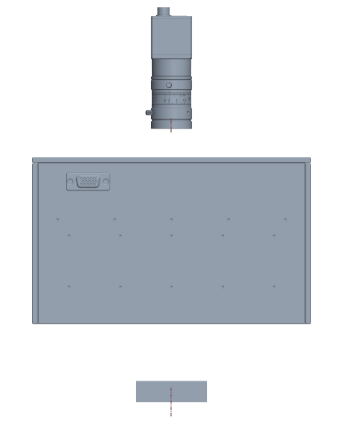

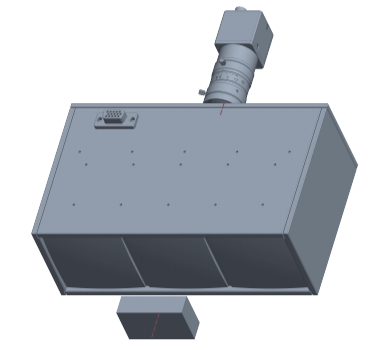

Self-developed optical imaging system

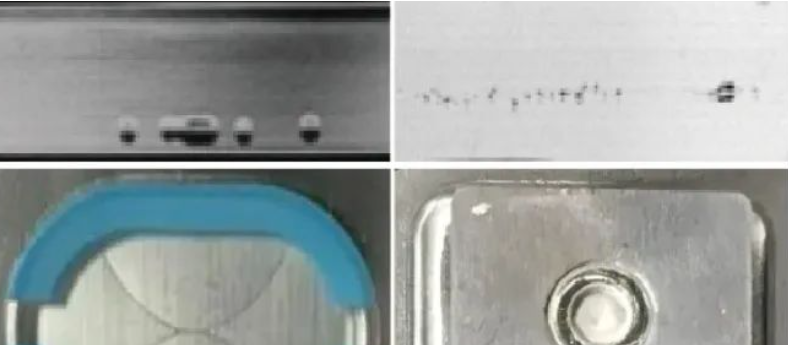

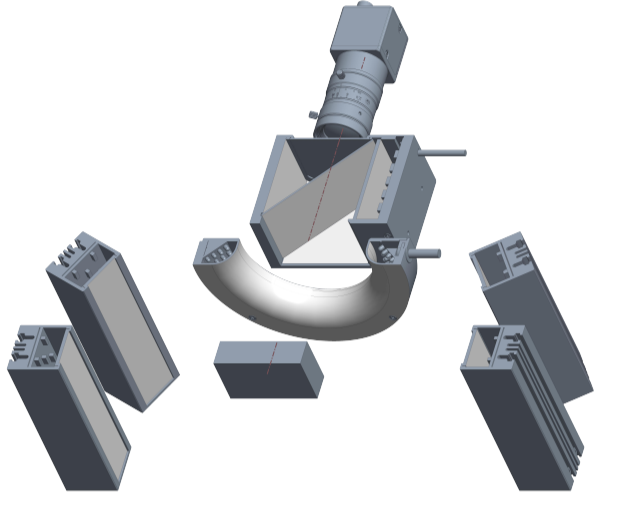

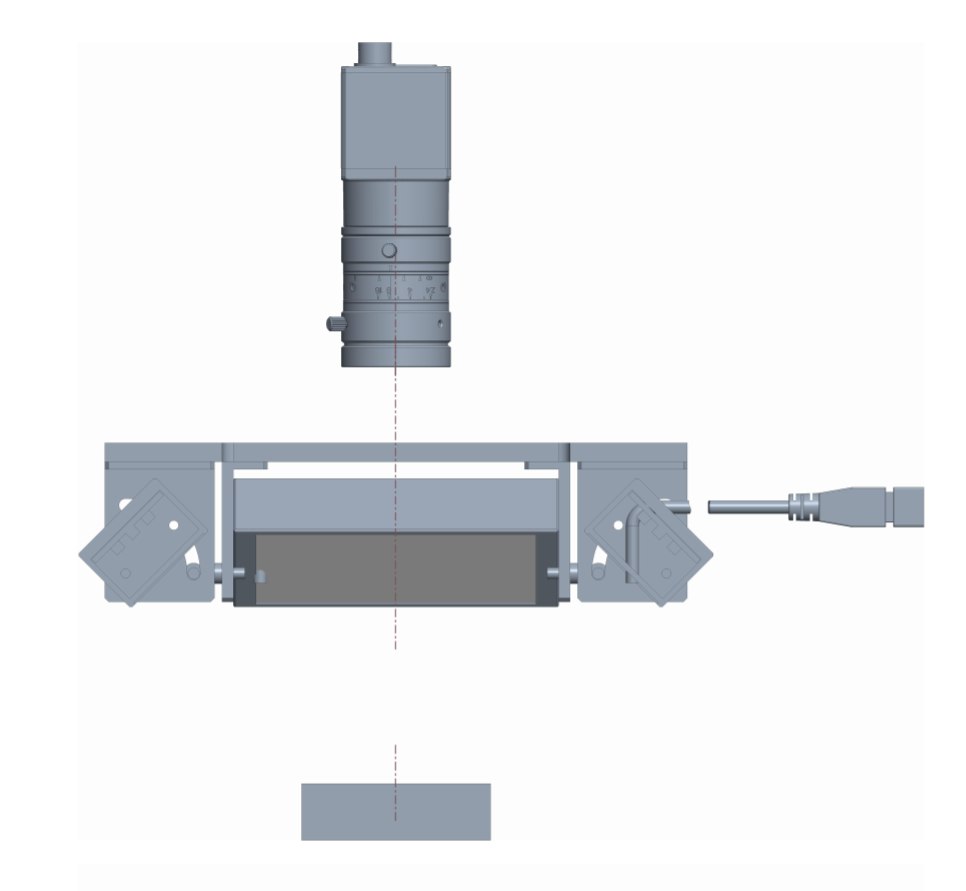

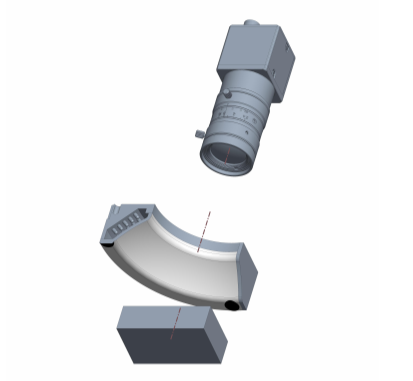

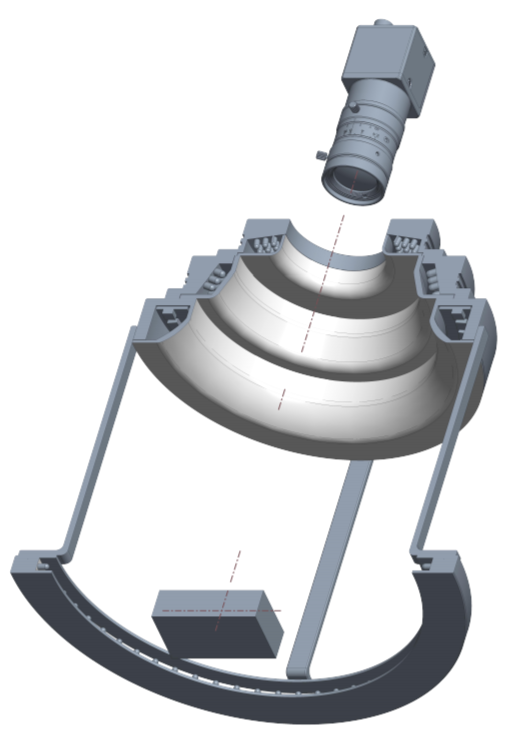

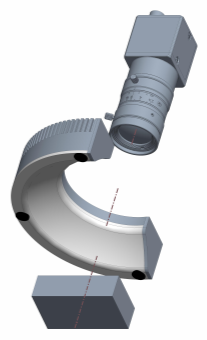

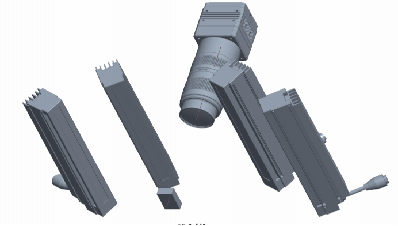

2.5D area + line scan imaging technology

Through the optical design of customized 2.5D surface light and 2.5D line scan camera, combined with different Angle light sources and corresponding image algorithms, shape images, positive reflection, diffuse reflection, etc., can be generated, and depth and height information can be clearly reflected through gray level changes.

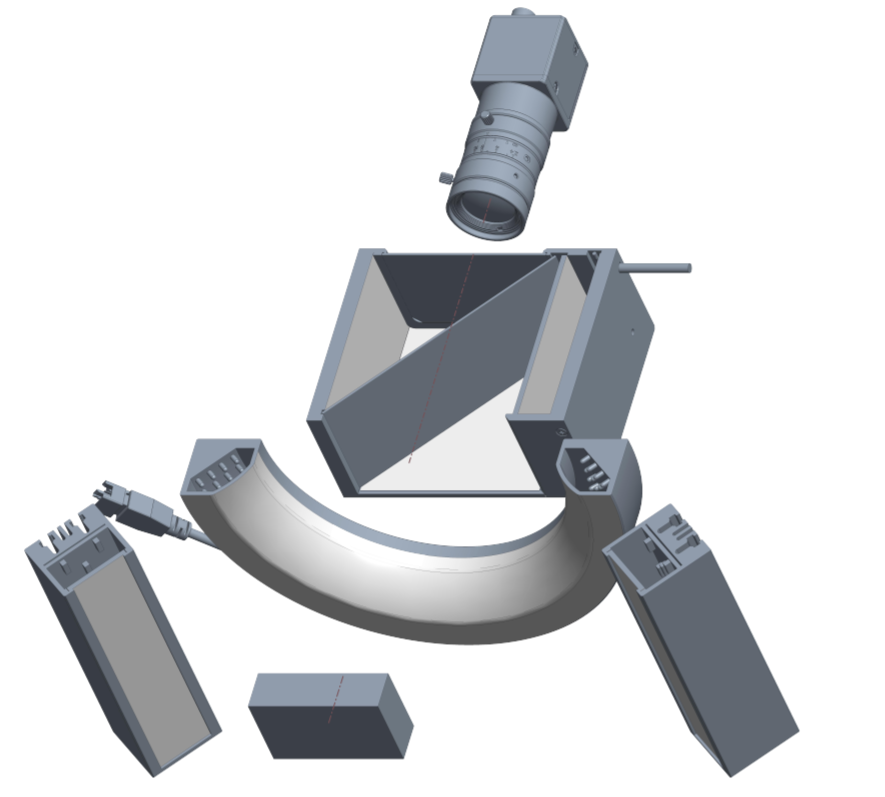

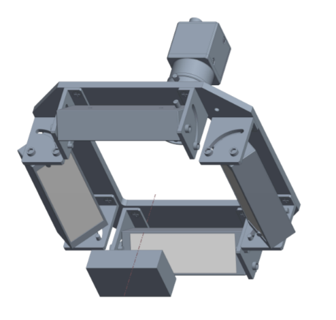

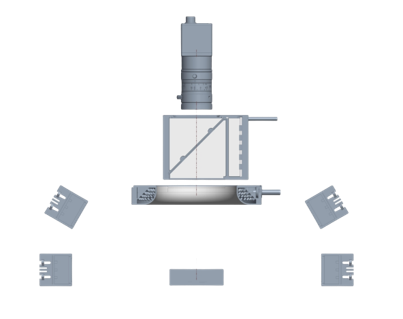

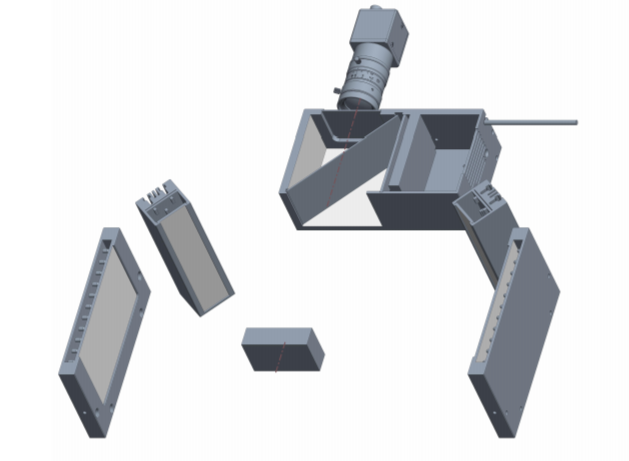

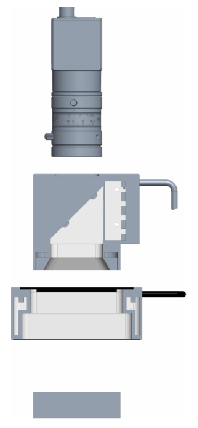

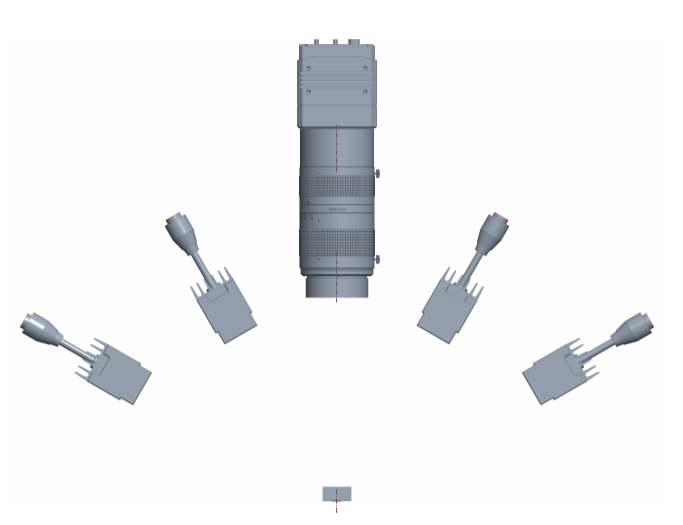

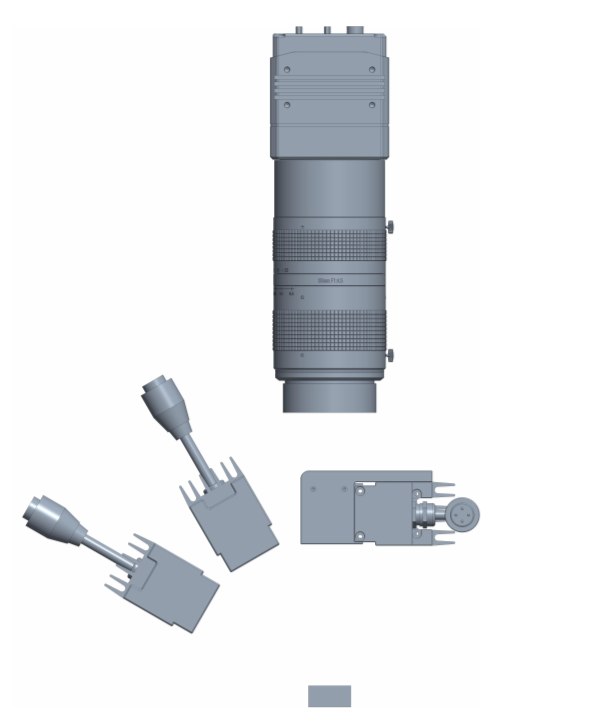

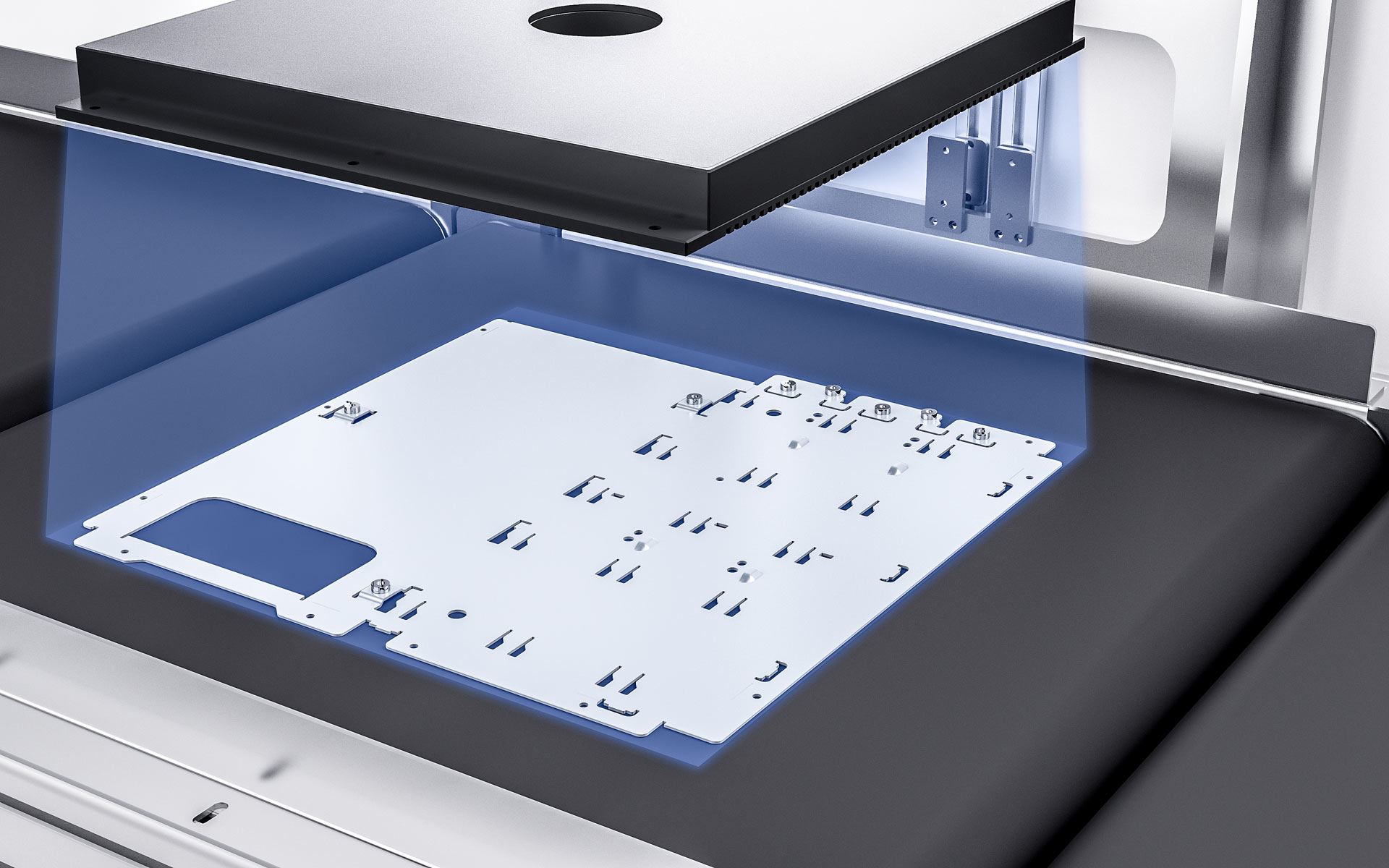

Customized multi-combination multi-wave 2D light source solution

Through the independent design of multi-zone, can independently control the Angle and brightness of the light source scheme, to ensure that the local reflective surface and directional defect features clear imaging, can solve such as foreign bodies in the film, directional scratches, large surface depression and other industry pain point imaging problems.

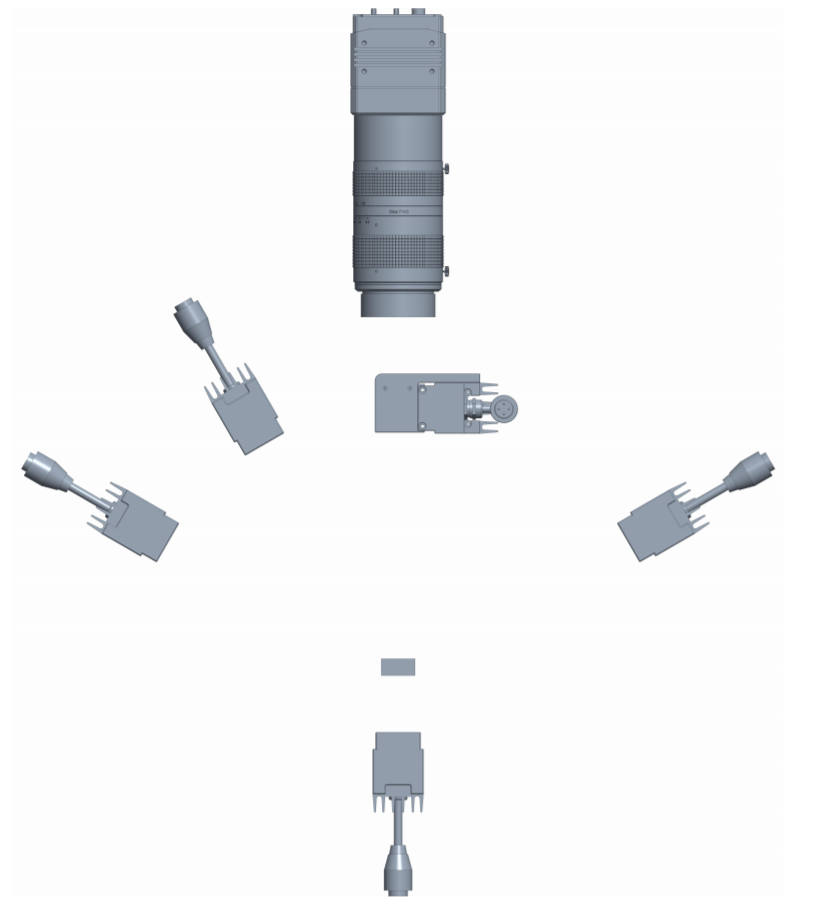

2D/2.5D/3D self-developed optical solution

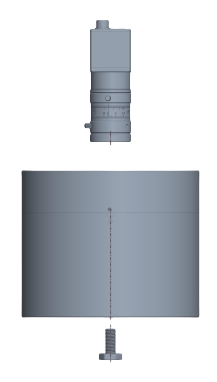

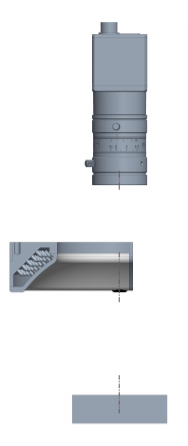

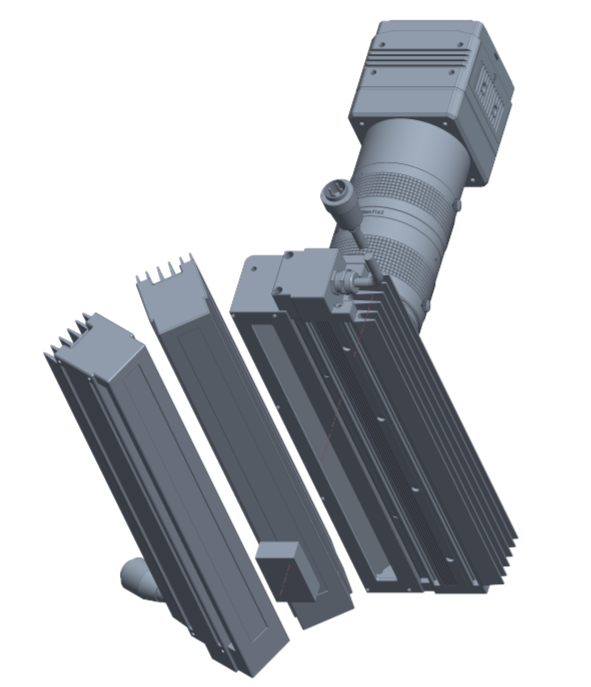

2D time-sharing stroboscopic line scanning + 3D line laser

2D time-sharing stroboscopic, single imaging can generate multiple images under different light sources and angles, saving CT time, reducing station erection and saving space; 3D line laser, for depth or height information features, to achieve a variety of surface state stability detection.

Customized light Source 2

Application scenario

①PCB substrate appearance inspection

②IC component appearance inspection

③Solder appearance inspection

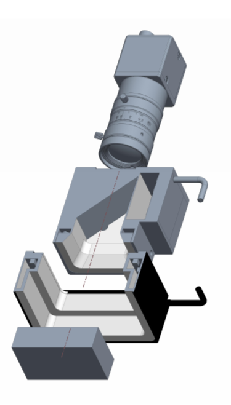

Customized light Source 1

Application scenario

①Highly reflective surface scratch detection

②Metal, glass object surface appearance inspection

③Concave and convex, curved surface appearance inspection

④Character detection

Partial optical solution

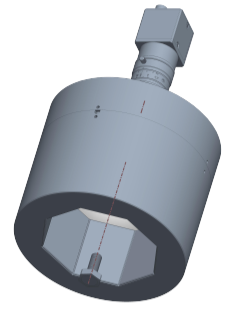

Customized light Source 3

Application scenario

①Plastic bottle cap character detection

②Food industry appearance inspection

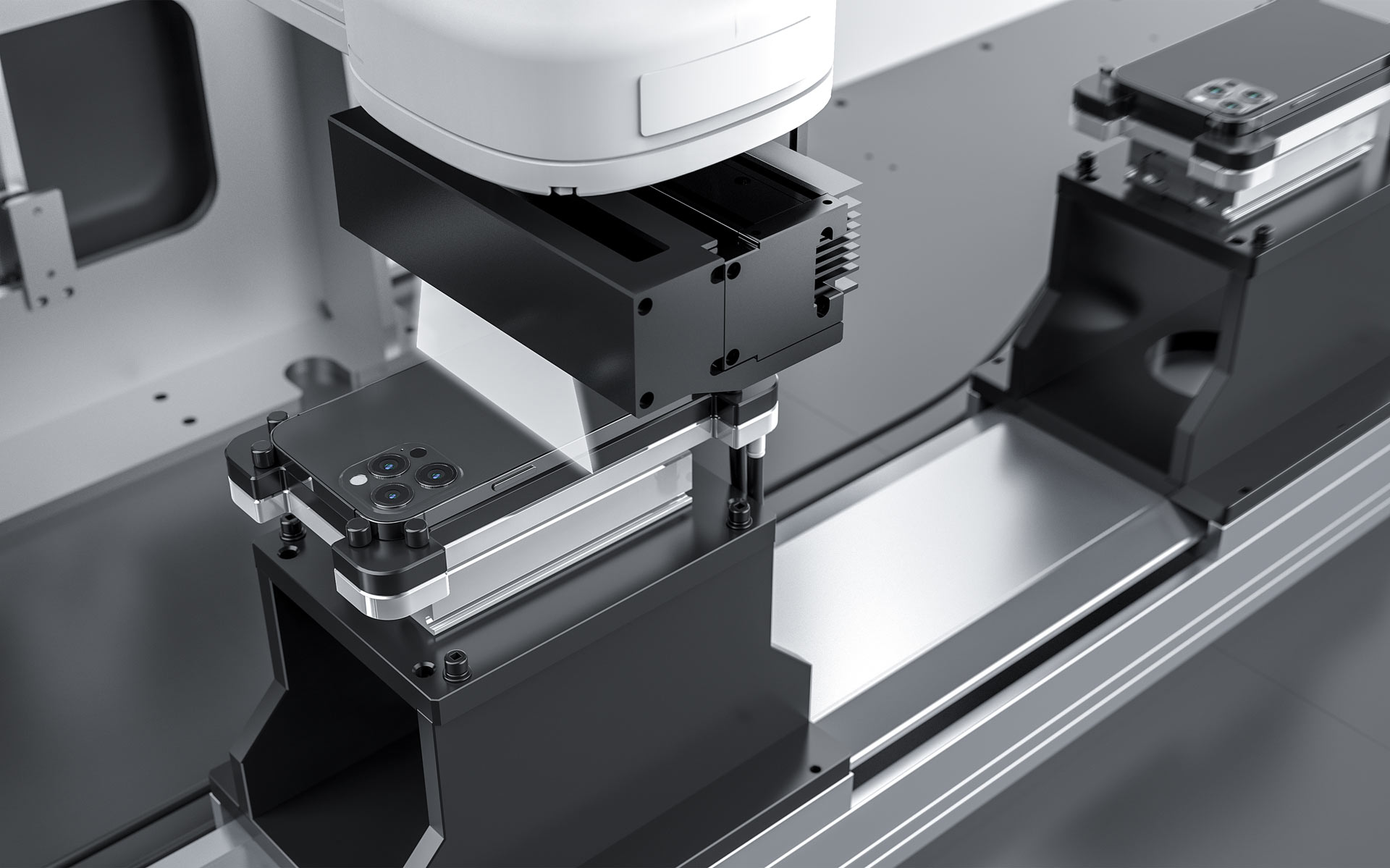

③Consumer electronics appearance inspection

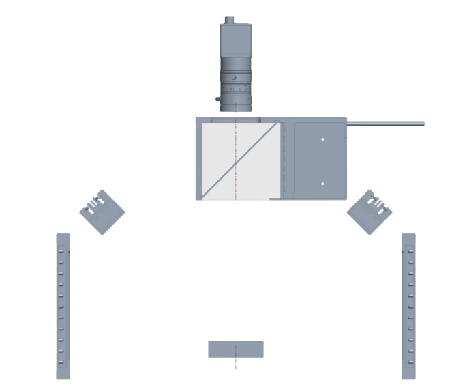

Customized light Source 4

Application scenario

①Auto parts appearance inspection

②Hardware product appearance inspection

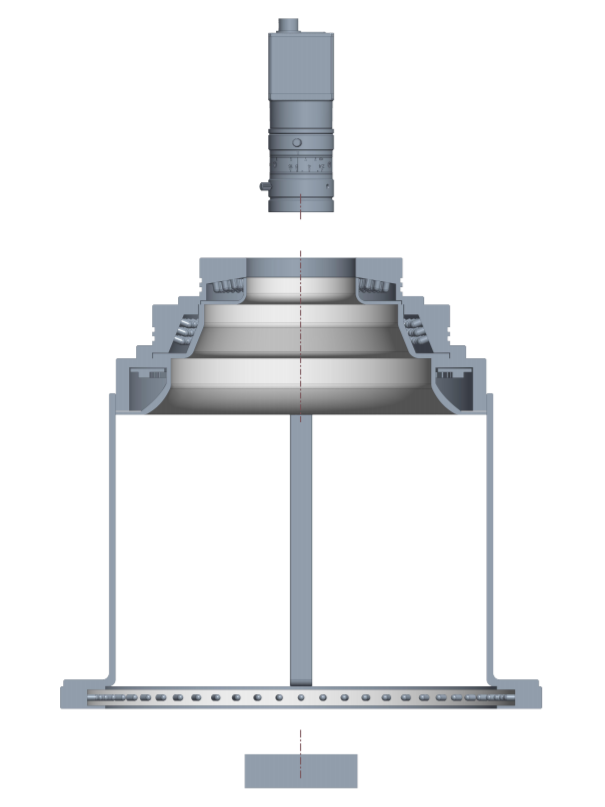

Customized light Source 7

Customized light Source 5

Application scenario

①Hardware product appearance inspection

②Food industry appearance inspection

③Pharmaceutical appearance inspection

Customized light Source 6

Application scenario

①Auto parts appearance inspection

②Hardware product appearance inspection

③Cylinder side detection

Application scenario

①Pharmaceutical industry appearance inspection

②Appearance inspection of electronic components

③Metal device appearance inspection

Customized light Source 8

Application scenario

①Multi-series electronic components appearance inspection

②Color bottle cap appearance inspection

Customized light Source 10

Customized light Source 9

Application scenario

①Auto parts appearance inspection

②Appearance inspection of electronic components

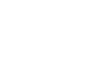

Application scenario

①Part size measurement

②Transparent object edge extraction

③Transparent sheet defect detection

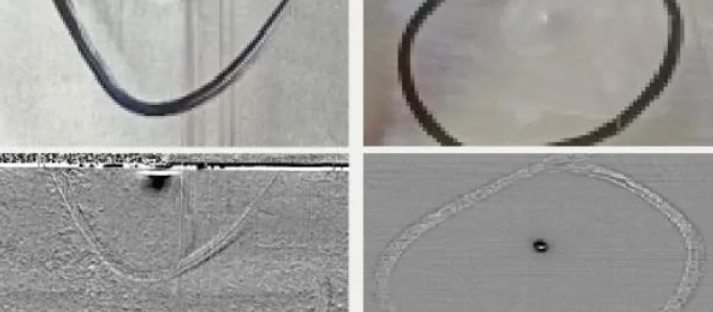

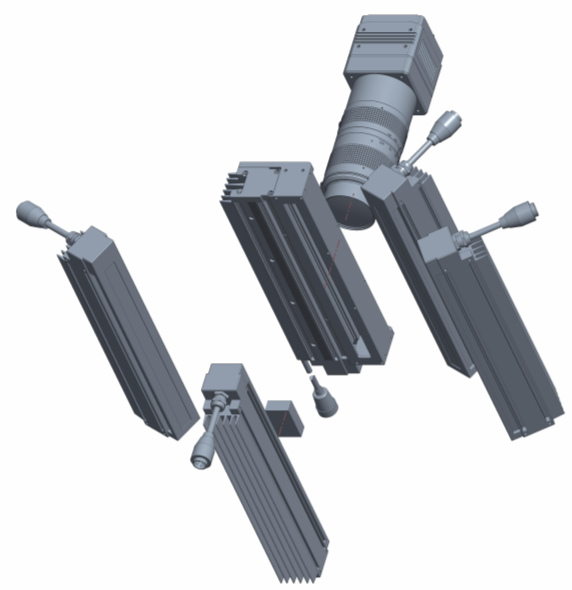

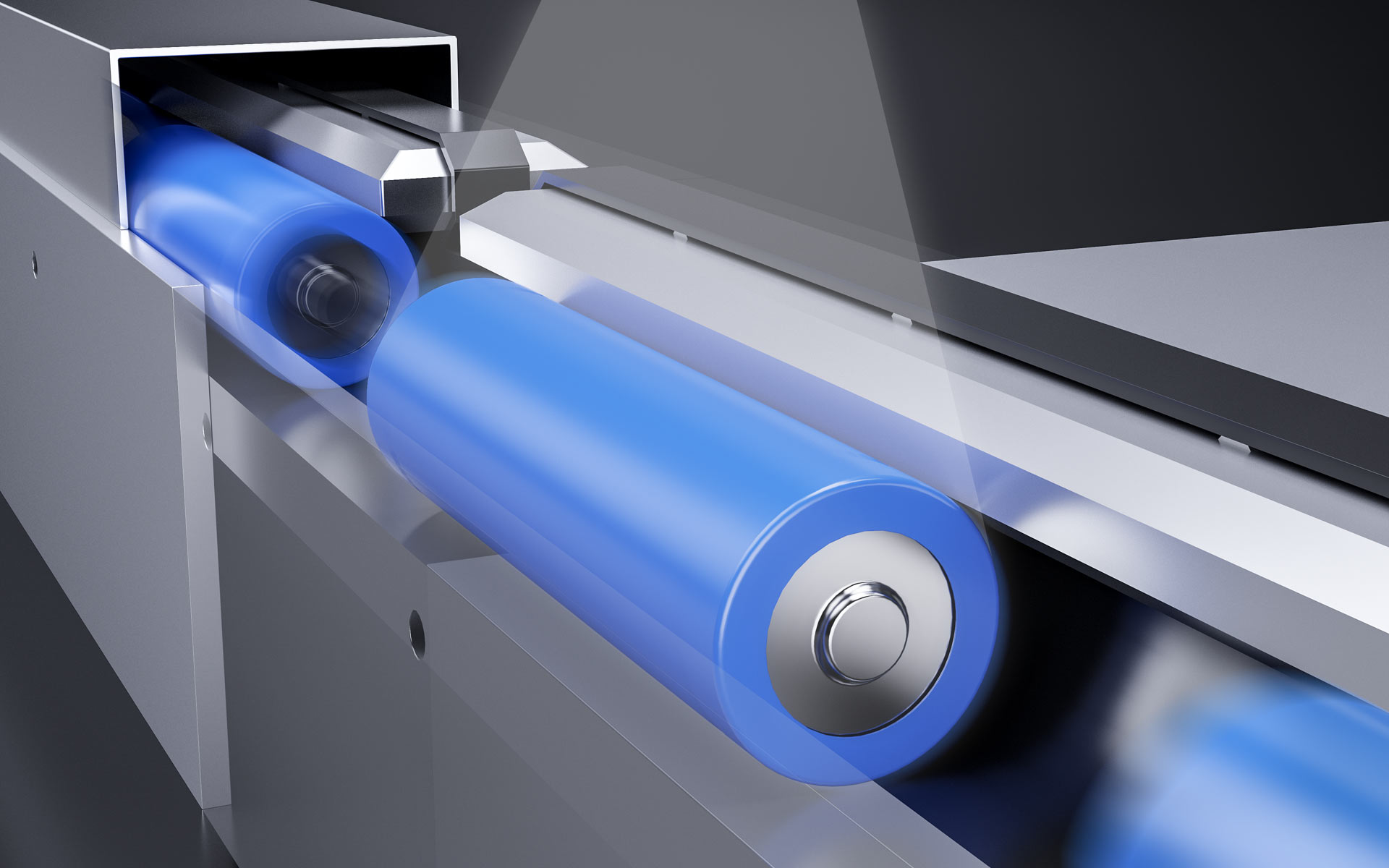

Time-sharing stroboscopic 1

Application scenario: Suitable for high-speed, large-area, high-precision fabric/coil/film defect detection and dimensional measurement scenarios.

①Food label characters and scratch detection;

②electrode inspection, white glass surface defects, cylindrical battery and soft pack battery surface appearance inspection;

Time-sharing stroboscopic 2

Application scenario

①New energy, automobile appearance inspection

②Transparent sheet, glass and other appearance inspection

Application scenario

Product Consulting

If you have relevant business needs, please leave a message